Carbon280 is a Perth-based materials science and engineering company. It is solving one of the biggest challenges to the uptake of green hydrogen: cost-effective storage and transport.

The company uses a patented method for storing hydrogen as a suspended magnesium hydride. This enables large volumes of hydrogen to be stored safely at atmospheric temperature and pressure.

‘Storage is a critical link in the hydrogen supply chain,’ says Mark Rheinlander, Chief Executive, Carbon280. ‘Our product – Hydrilyte® – can deliver hydrogen when and where industry needs it –affordably and at scale.’

The challenge: green hydrogen and intermittency

Hydrogen is critical to decarbonising hard-to-abate sectors like steelmaking and chemicals. But the transition to renewable hydrogen faces a bottleneck: supply is intermittent, while industrial usage is not. This means industrial-scale uptake is dependent on finding new ways to store hydrogen.

‘Liquid hydrogen is expensive to produce and hard to store for long periods of time,’ explains Rheinlander. ‘Ammonia is toxic. It is costly to handle and costly to crack. What we need is a “carrier”: a hydrogen compound that can be handled like diesel, but which readily stores hydrogen.’

Making hydrogen easily transportable

Carbon280’s product – Hydrilyte® – is a magnesium powder suspended in mineral oil. The magnesium reacts with hydrogen to form a solid-state magnesium hydride. This hydride acts as a physical carrier for hydrogen.

Unlike ammonia or liquid hydrogen, Hydrilyte® is non-toxic and non-flammable. It does not need to be pressurised. According to Rheinlander, it is transportable at room temperature via existing trucks, ships and pipelines.

‘This marks a breakthrough in making hydrogen a practical source of industrial energy,’ says Rheinlander. ‘With Hydrilyte®, you can literally carry hydrogen in a bucket.’

Piloting the technology in Western Australia

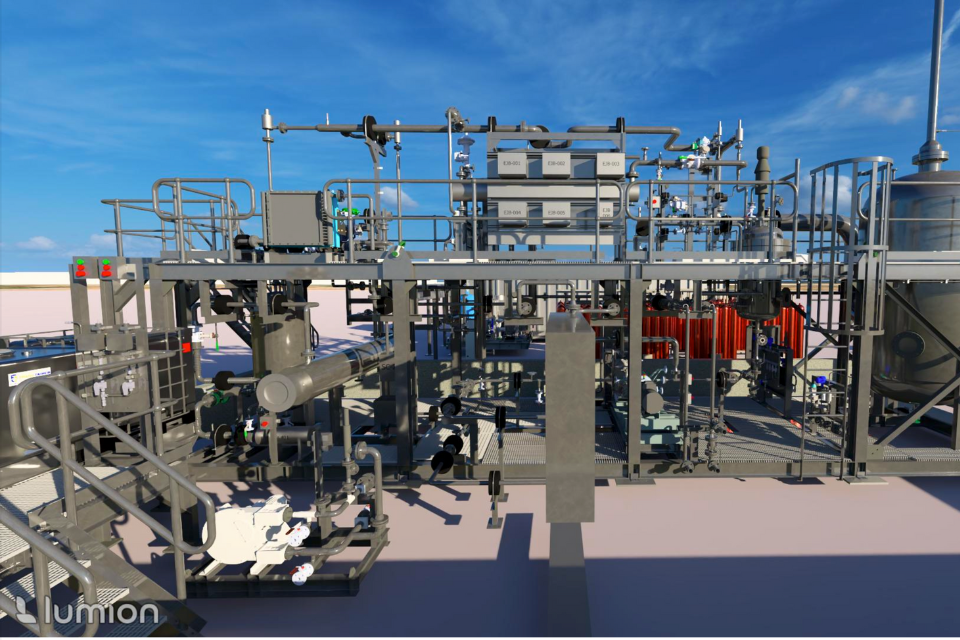

Carbon280 has built a A$14.4 million Hydrilyte® Technology Pilot (HTP) at its Research Centre in Kwinana, Western Australia. The facility – currently at ‘Technology Readiness Level 6’ – benchmarks Hydrilyte® performance in terms of energy efficiency, stability and system-level costs.

The HTP will enable hydrogen developers to calculate the cost of storing hydrogen using Hydrilyte® technology.

Carbon280 also opened a Hydrilyte® laboratory in January 2025. The laboratory is conducting applied materials research to optimise Hydrilyte® performance. Its goal: to generate additional patents that reinforce this product’s game-changing potential.

Carbon280’s Hydrilyte® Technology Pilot at its Research Centre in Kwinana, Western Australia.

Global potential for a clean energy enabler

Since 2022, Carbon280 has raised A$10.6 million in funding, led by Woodside Energy and UK-based Hive Energy. It was named Energy Gamechanger of the Year by Energy Club WA in December 2023.

In 2025, Carbon280 partnered with natural hydrogen explorer, H2EX. The partnership is evaluating applications for the single-step separation and storage of hydrogen from natural hydrogen mixed-gas streams. This will simplify storage options and enable distribution of hydrogen to customers via diesel trucks or slurry pipelines.

‘Hydrilyte® is not just a breakthrough for hydrogen, it’s a breakthrough for global decarbonisation,’ says Rheinlander. ‘With our technology pilot nearing completion, we’re seeking developers and partners to roll this out globally.’

Working with Austrade

Since 2022, Rheinlander has partnered with Austrade at the annual World Hydrogen Summit in Rotterdam to promote his technology in Europe.

‘The Australian stand has set the standard,’ he says. ‘It provides visitors with a one-stop-shop for most links in the hydrogen supply chain.

‘The juxtaposition of breakthrough technology companies with traditional energy companies instils confidence in Australia. It shows we have the capacity, not just to survive the energy transition, but to thrive on it.’

Go further, faster with Austrade

Austrade’s Go Global Toolkit helps you learn the export basics, find the right markets and understand market requirements.